Choosing the Right Stacker for Small and Medium Businesses in India

Running a small or medium-sized enterprise (SME) warehouse in India means juggling inventory, space, and cost; all while aiming for efficient operations. Selecting the best stacker for SME warehouse in India can transform your workflow by simplifying material handling, maximising space, and improving safety. But with multiple stacker types and capabilities available, how do you choose one that perfectly fits your industrial unit’s size and budget? This guide is designed to provide industrial unit owners, operations managers, and purchasing managers with clear insights to make an informed choice.

Why Stacker Choice Matters for SMEs

SME warehouses usually have limited space and resources, so investing in the right stacker ensures smooth movement of goods without overspending or operational delays. Stackers help lift, transport, and stack materials vertically, enabling better use of warehouse space and reducing manual labour risks.

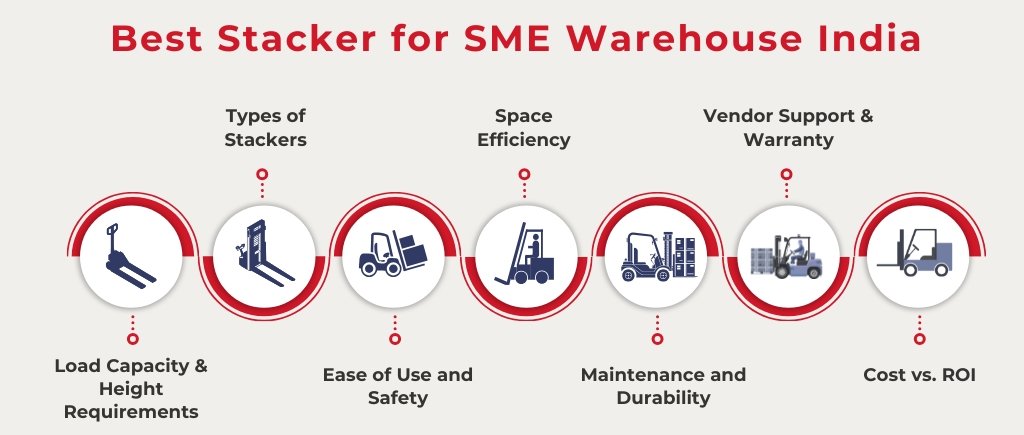

Key Points to Consider

-

Load Capacity & Height Requirements:

- Evaluate the average weight of goods you handle. Stackers come in various load capacities, typically ranging from 1 to 3 tons.

- Consider the maximum stacking height needed. SMEs with low ceilings might need compact, low-lift stackers, while others may require reach stackers for higher shelves.

-

Types of Stackers:

- Manual stackers are budget-friendly and great for light loads and short distances.

- Electric stackers reduce operator effort and suit higher volumes and longer transport distances inside warehouses.

- Semi-electric stackers offer a balance with manual steering but powered lifting, ideal for moderate use.

-

Space Efficiency:

- For tight aisles, narrow stackers with small turning radii save crucial space while maintaining manoeuvrability.

- Consider foldable or adjustable fork designs for added flexibility in stacking various pallet sizes.

-

Ease of Use and Safety:

- Look for stackers with ergonomic controls, clear visibility, and safety features like overload protection and emergency stop buttons.

- Training needs vary; electric models usually require some operator familiarisation, whereas manual stackers are simple but physically demanding.

-

Maintenance and Durability:

- Electric stackers demand battery upkeep and regular servicing but offer longer operational uptime.

- Manual stackers need minimal maintenance and fewer spare parts, ensuring lower ongoing costs.

-

Cost vs. ROI:

- Evaluate your budget but also calculate returns through labour savings, increased throughput, and reduced injury risks.

- Investing in a slightly higher-priced electric or semi-electric stacker often pays off through enhanced productivity over time.

-

Vendor Support & Warranty:

- Choose reputed suppliers offering prompt service, availability of spare parts, and warranty coverage for hassle-free equipment lifecycles.

Final Thoughts

Choosing the best stacker for SME warehouse India means aligning your operational needs with your budget and space constraints. Investing time in understanding stacker types, capacities, and user-friendliness will yield long-term benefits in efficiency and workplace safety.

Unlock options and reliable support from local experts like hand pallet truck manufacturers in Coimbatore to equip your warehouse